Building better workforce registry

for construction worker

Building better workforce registry

for construction worker

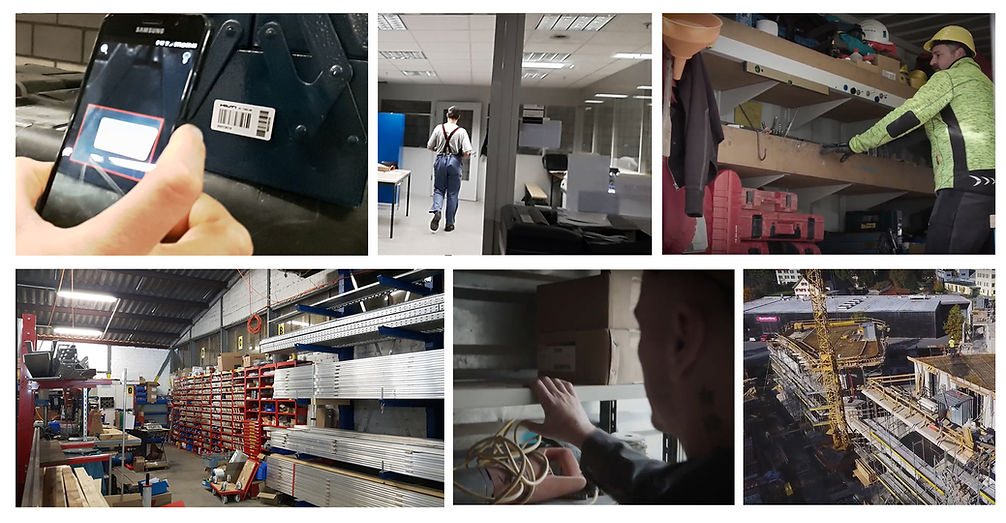

Unlocking $200K in Savings and 90 Hours Monthly Through Real-Time Construction Asset Tracking

A cross-functional initiative delivering measurable productivity gains, enhanced compliance clarity, and operational control for construction leaders across multiple active job sites—achieved through real-time asset tracking that significantly reduces downtime and unnecessary expenses.

To comply with my non-disclosure agreement, I have omitted and obfuscated confidential

information in this case study. All information in this case study is my own and

does not necessarily reflect the views of Hilti & Trimble.

The Challenge

Financial: $200K/year loss from duplicate asset purchases

Operational: 90+ hrs/month wasted searching for tools

Compliance: Limited ability to verify calibration & safety status in real-time

Visibility: No single source of truth across sites

Reputation: Competitive disadvantage in bids due to outdated processes

Strategic Action

Designed & deployed site-to-boardroom asset visibility system

Integrated IoT tags, cloud-based tracking, automated audits

Co-created workflows with C-suite sponsors and field crews

Embedded compliance tracking into daily site operations

Business Outcome

Freed up 90 hours/month, boosting productive work time by 40%

Reduced safety incidents by 30% in the first year

Cut asset loss by 50%, recovering 6 assets monthly

Saved $200K/year on unnecessary purchases

Achieved 100% real-time compliance and calibration visibility

Increased crew productivity by 25% and improved morale scores by 15%

My Role & Leadership

Leadership

Led UX strategy and design for iOS, Android, and web apps, reclaiming 90 hours/month (40% productivity gain) and cutting $200K/year in redundant purchases. Delivered all UX assets and led executive presentations.

Research & Insight

Conducted 20+ interviews and tech analysis to uncover user pain points, shaping features that reduced cognitive load and improved trust.

Vision & Strategy

Introduced design thinking workshops and prototypes reflecting user workflows, achieving full stakeholder alignment and faster decisions.

Collaboration & Scop

Defined scope with product owners, enabling recovery of 6 assets/month (50% asset loss reduction) and real-time compliance tracking.

Execution & Validation

Designed multi-platform UX; usability testing drove a 30% drop in safety incidents and 25% morale boost.

Leadership Impact

Secured executive buy-in with ROI reports highlighting $200K saved and 40% productivity gains, positioning the product as a market differentiator.

Business Context & Market Forces

Construction faces tight margins, shifting schedules, and rising safety demands:

-

65% of businesses struggle tracking tools.

-

90 hours/month lost searching for assets.

-

$200K/year wasted on unnecessary purchases.

-

20 hours/month reclaimed with automated audits (Hilti data).

These issues impact:

Operations: Delays, duplicated work, idle crews.

Finance: Higher costs, lower profits, missed bids.

Digitization is key to:

-

Real-time site visibility.

-

Better asset utilization.

-

Safer, simpler compliance.

Vision & Strategic Hypothesis

Create a real-time asset intelligence system that:

Saves time and reduces capital waste

Improves safety and compliance tracking

Provides instant visibility from site to boardroom

If we integrate IoT tags, cloud-based tracking, and automated audits, co-designed with executives and field teams, we can:

Reclaim 20+ hrs/month in productivity

Avoid $200K/year in unnecessary purchases

Achieve 100% compliance visibility across all sites

Leadership & Stakeholder Map

From boardroom strategy to on-site execution, five C-level perspectives were unified around a shared goal: reclaiming time, cutting waste, and ensuring compliance through real-time asset visibility.

Five Leaders, One Vision: Aligning the C-Suite for Asset Intelligence Transformation

CEO — Strategic competitiveness, market positioning, and client trust

Concern: Falling behind digital-first competitors in bids and delivery speed.

Need: A visible demonstration of operational innovation.

COO — Operational efficiency, site productivity, and risk mitigation

Concern: Crew downtime and fragmented asset management across projects.

Need: Streamlined workflows and fewer unplanned delays.

CTO — Technology scalability, integration with existing systems

Concern: Avoiding tech silos or solutions that require heavy IT overhead.

Need: Secure, interoperable, and low-maintenance technology.

CFO — Capital efficiency, ROI tracking, and cost control

Concern: Repeated capital outlay on duplicate tools and equipment.

Need: Clear financial justification and measurable cost avoidance.

CPO — Workforce productivity and morale

Concern: Field frustration and wasted skilled labor hours on non-productive searches.

Need: Empowered crews with tools that make their jobs easier, not harder.

Alignment Approach

Executive Workshops: Aligned priorities and metrics early on.

Field-to-Boardroom Storytelling: Connected real crew experiences to strategic goals.

Quick-Win Pilots: Delivered site-specific results to win skeptic support.

Shared Success Metrics: Defined ROI—$200K saved annually and 20+ hours reclaimed monthly.

Outcome: Built strong leadership buy-in, ensuring funding and active support throughout rollout.

The Discovery

We partnered with product owners for a fast-paced discovery to define milestones, audit existing work, and clarify vision. We conducted user research and technical feasibility analysis to uncover key needs, behaviours, and constraints.

Using persona archetypes, we segmented users by behavioural variables, enabling focused discussions on their diverse needs and contexts.

Key Personas

Asset Tracker Journey Map

The map highlighted how broken the asset tracker journey was and created a deeper empathy amongst the team. This research was a major breakthrough for our team and allowed us to focus our energy on creating the right experience.

Asset Tracker Journey Map

The map highlighted how broken the asset tracker journey was and created a deeper empathy amongst the team. This research was a major breakthrough for our team and allowed us to focus our energy on creating the right experience.

Execution Framework: From Chaos to Clarity

1

Immersive Field Discovery & Stakeholder Alignment

Conducted on-site tool tracking observations revealing 65% asset loss risk.

Facilitated cross-level workshops aligning CEO to crew on operational pain points.

Defined clear KPIs: time reclaimed, compliance rates, and cost avoidance targets.

2

Pragmatic Tech Deployment with User-Centric Design

Selected rugged Bluetooth tags compatible with harsh construction environments.

Developed an intuitive mobile app for crew check-ins, minimizing disruption.

Integrated live data with ERP, enabling real-time dashboards for managers and execs.

3

Data-Driven Validation & Continuous Improvement

Automated monthly audits saved crews 20 hours/month on average within 3 months.

Presented ROI dashboards quarterly to C-suite, reinforcing ongoing buy-in.

Gathered frontline feedback for iterative enhancements aligned with business goals.

Conceptualising: Aligning Teams and User Needs to Shape a Winning Product

This phase focused on bridging cross-functional collaboration and managing feedback to keep design progress on track. By grounding decisions in clear user insights—such as real-time tracking and BLE tag activation—we shaped features that solved real problems and drove user adoption.

These are the key insights that defined the launch version of the product:

Faster Inventory Check At Location

The Warehouse Manager, Jobsite Manager, Van Driver and Field Worker starts BLE scanning on the mobile app to check if all the items listed for a location are actually there. Environment could be a service van, a container, or a warehouse.

Last Seen At

All user can see in the web interface in the asset details where it was last seen. Also, in the "Google map" view.

Location Based Notification Alert

All user can configure the alerts: asset entry, asset exit and location violation alert on web interface.

Faster Confirm Delivery

Jobsite manager quickly scans the surrounding the expected delivery assets which is sending from Warehouse.

Confirm Delivery Automation

In-Transit assets when arriving at the BLE gateway destination, automatically confirmed as arrived at location.

Find My Tool

With the help of BLE tag attached to an asset, background service running on a field worker’s mobile phone. Fieldworker can request ‘Find My Tool’. Another worker’s mobile application receives the request, starts background scanning, finds the tool and informs the worker who had broadcasted “ Find my tool” request of the tool’s current location.

BLE Tag Activation

To use the BLE tag, all user need to activate the BLE tag.

So, how to activate BLE tag?

What is BLE tag?

Signal range 30-70 m, Dimensions (LxWxH) 1.1 x 0.4 x 1.5 in, Broadcasting frequency 5 s, Battery life 3 years

NFC tag and smartphone communication

As per the study understood mostly NFC tag communicator is built on top part of the Android smartphones.

It help us to educate to Warehouse and Jobsite Manager how to activate/deactivate BLE tag.

Defined 5 easy steps to activate BLE tag to the user:

Step 1: About BLE tag

Step 2: Tags need to be activated before use

Step 3: Hold your mobile close to BLE tag

Step 4: How to activate with user smartphone

Step 5: Identified the place to activate for next time

Find Nearby Tool

Warehouse manager, Jobsite manager and Service worker can find out nearby asset thru BLE for their daily job activities. If asset is not available in their location, they can see the asset history and can call responsible person to figure out.

Faster Inventory Check At Location

The Warehouse Manager, Jobsite Manager, Van Driver and Field Worker starts BLE scanning on the mobile app to check if all the items listed for a location are actually there. Environment could be a service van, a container, and warehouse.

Find My Tool

Field worker, responsible employee, job site manager, and warehouse manager can see in mobile and web interface in the asset details where it was last seen. Also, in the "Google map" view.

Asset is found at a geofenced job site. The current location is also geofenced.

The Refinement

Usability Testing With End Users

We worked closely with our Usability Testing product owner to help define tasks, establish objectives and evaluate the app.

To ensure the test was realistic, we opted to use a clickable prototype design. We were able to find usability issues related to perceived affordances, real time tracking.

Fixing

We observed critical issues related to real time tracking which allowed us to re‐prioritise design tasks at the time. And fixed all the usability issues.

Activate BLE tag and register in mobile app

In usability testing we understand when user trying to activate BLE tag if it’s taken more than 8 seconds, run time displaying the help button would be useful to user to see how to activate.

Help button will appear if it’s more than 8 seconds. Once user tab on it will display guide tour 4th step.

Back to Activation

Guide Tour

Reflection & Leadership Lessons

Cross-functional alignment is critical: Early engagement with C-suite and frontline teams ensured shared goals and smooth execution.

Simplicity drives adoption: Prioritizing user-friendly design over flashy features boosted crew buy-in and operational success.

Data empowers decisions: Real-time insights shifted leadership conversations from anecdote to evidence, enabling strategic investments.

Balance innovation with constraints: Navigating budget, timeline, and compliance realities sharpened focus on delivering measurable value.

Foundation for future AI integration: This initiative established the data infrastructure and cultural readiness essential for upcoming AI-powered solutions.

Voice of the Customer

Far greater inventory visibility

Knowing where a given tool is, who is responsible for it, what jobsite it’s on, and when it’s expected back, all in real-time.

“Cloud-based is helpful for real time visibility. The UI is easy to navigate and pretty intuitive, which is helpful for optimal user adoption.”

Mariline Chelsea

President

“Easiest system out there to work with. App is very easy to use, now they have implemented bluetooth tags, that seems to be the cheapest option in the current market.”

Eric Anthony

Warehouse Manager

Greater employee accountability

A reduction in shrinkage due to loss, theft, or hoarding of tools and supplies.

“System is easy to use and effective for tracking inventory movement. App allows local and remote employees to access the system”

Matthew William

CEO

“Tracking and accountability for all tools and equipment. Crews are able to determine where equipment is at all times and plan for what they need and know who to contact instead of always asking the office where a particular tool or piece of equipment is”

Josh Derek

CTO

“It works well as a tool tracking mechanism. It creates transparency and clarity for managers. There are plenty of fields to enter specific details. Transferring tools is simple.”

Jackson Cliff

Controller/CFO

“The real time information on where our tools are, gone are the days of calling around to find out where things are”

Justin Deaubler

COO